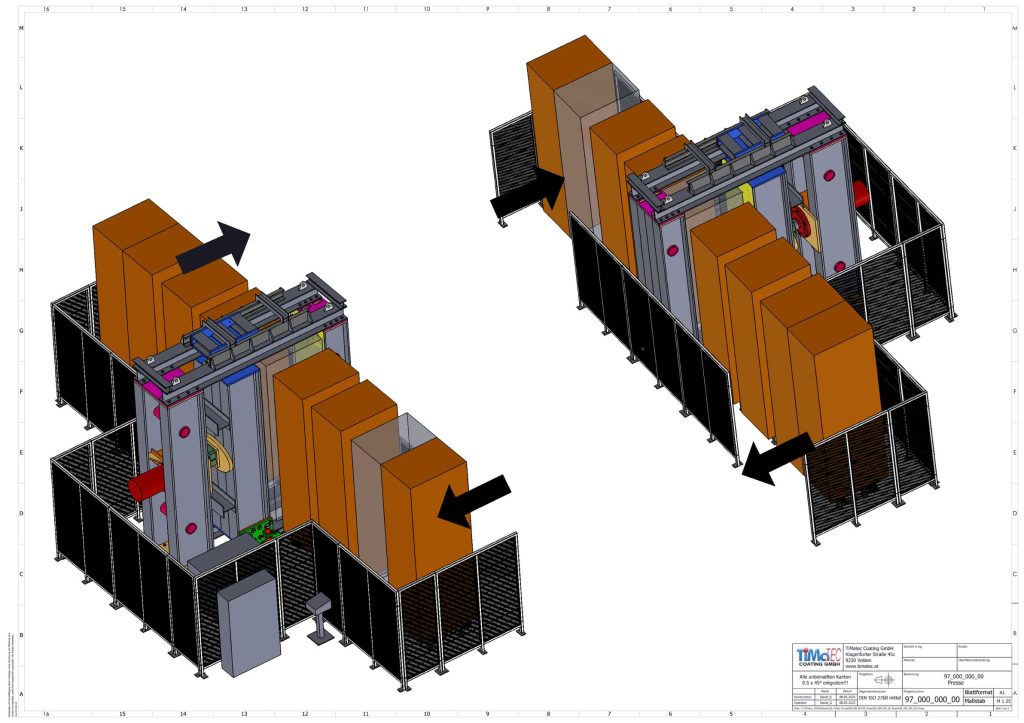

EPS BLOCKPRESS Z 1 Type 400 or 5000

EPS BLOCK PRESSING up to 6.0 m block lengths

for impact sound quality and against facade panel curvature

TIMATEC COATING GMBH has a great deal of experience in the correct design and suitable construction of such EPS block press machines. A total of 12 EPS block presses up to a max. Block length of 6.0 m in use with a weight of 35 t. The block pressing depth complies with the standard and is 60 % of the maximum block pressing depth. Block size for underfloor heating with impact sound quality. A pressing depth of 10 % or 15 % is usual for the façade blocks with one or two pressing steps.

In the meantime, only type Z 1 block presses in vertical design with a single hydraulic press cylinder up to 230 bar pressure and 250 t (2,500 KN) pressing force are used. This EPS block press in

vertical design

with only one cylinder has been patented and may only be built and supplied worldwide by TiMaTEC Coating GmbH .

Of this new press type incl. block transport system with 8 blocks in the system, 4 systems are already operating very satisfactorily. The first EPS block press of the new type Z1 delivered has been in operation near Frankfurt since 2020 and has already completed 20,000 operating hours without a fault.

This press works in fully automatic mode without operating personnel and is only supplied by an automatic block transport system or with the usual forklift truck. Pressing options in one machine are also possible with different block lengths of, for example, 4.0 m and 5.0 m block length with a block pressing depth of 1.4 m.

EPS block pressing with a density of up to 30 is also very suitable for preventing “

panel curvature

” and has shown good results for the use of these as façade panels at a compression of 10 % to 15 % of the EPS block compression dimension.

Further shrinkage of the subsequently cut panels in the floor and façade areas is then no longer present. We previously also had these EPS block presses in a horizontal version, but now only have a vertical version in our product range.

These machines work in fully automatic mode and do not require any operating personnel. The appropriate block formats are placed on the transport system using a forklift truck. Depending on the length of the block transport section, there may be several blocks in the waiting position. The further transport of these blocks into the pressing chamber takes place automatically.

When the program is set to “AUTO” and the start button on the control panel is activated, automatic mode is initiated. By forklift truck or autom. block transport system (DS-Automotion), one or two EPS blocks are placed on the conveyor belt at the same time. Depending on the program selection the block transport and block pressing in the pressing chamber takes place automatically and is then transferred to the outfeed conveyor for collection by the forklift or an automatic forklift truck. block transport system, either one block or two blocks can be lined up together at the same time.

Maschinen- und Anlagenbau

A-9220 Velden(Austria)

Klagenfurter Straße 45c

Phone: 0043 680 333 2818

E-mail: tischler@timatec.at